Wound Rotor Induction Motor vs Squirrel Cage Induction Motor

Energy is necessary for most applications, and there are many ways to produce energy. One of these ways is using an induction motor in AC electric motors. The electric motor obtains electric current through electromagnetic induction from the rotating magnetic field of the stator winding. To better understand the application of these elements, it is crucial to look into the various applications of these motors. The two standard rotors are wound rotors and squirrel cage rotors. They have slight differences that we will explain to help you make the best selection.

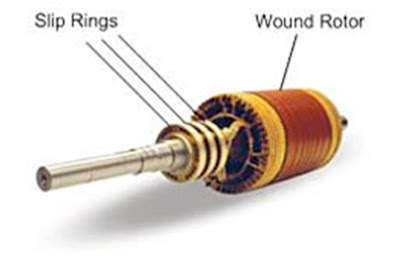

Wound Rotor Induction Motor

A wound rotor, also called a slip ring motor or phase wound motor, is a conventional type of induction motor with a conventional three-phase winding. It has a laminated cylindrical core with a semi-closed slot on the outer periphery and contains a three-phase insulated winding. The rotor winding is equal to the number of poles at the stator. The three finish terminals connect to form a star point, and the three start terminals connect to three copper slip rings on a shaft.

Squirrel Cage Induction Motor

The squirrel cage motor is an induction motor with a squirrel cage. It features a simple and rugged construction. The motor rotor comprises a cylindrical laminated core with semi-closed circular slots and a short circuit on all ends held by a copper or aluminium ring. This ring is called the short circuit ring, and you cannot add any external resistance to the circuit rotor.

Differences between a Rotor Induction Motor and Squirrel Cage Induction Motor

The major difference between a wound rotor and a squirrel cage motor is that the former has an external resistance circuit controlling motor speeds. The squirrel cage motor cannot add any external circuit because the motor’s bar is permanently fixed onto the ring end. Other differences are explained below.

Comparison between Wound Rotor vs Squirrel Cage Motor

- The wound rotor motor has a slip ring induction motor, while the squirrel cage motor uses a squirrel cage rotor.

- The sling ring motor has a rotor with a cylindrical core and parallel slots with bars. On the other hand, the slots in a squirrel cage motor are not parallel.

- The wound motor is complicated because it has a slip ring and brushes, whereas the squirrel cage motor features a simple construction.

- A wound rotor has an external resistance circuit, while a squirrel cage motor does not allow the addition of any external resistance circuit. It is because the rotor bars are fixed permanently.

- Slip ring motors are more costly to maintain than squirrel cage motors because wound motors have brushes and rings.

- Slip ring motors experience high copper loss than squirrel cage motors.

- A wound motor uses brushes to transfer power, whereas squirrel cage induction motors do not.

- The phase wound motor is ideal for applications requiring high starting torque, like lifting cranes. Unlike the phase wound motor, the squirrel cage motor is typical in drilling applications.

- Wound motors have low starting currents because of the resistance circuit control. Alternatively, squirrel cage motors have higher starting currents.

One reason to understand the differences between these rotors is to avoid bypassing the overload capacity. A qualified motor manufacturing company may suggest using a squirrel cage rotor because it is easy to maintain. However, heavy applications can use wound rotor induction motors with higher starting torque.

Read more blogs – silentkeynote